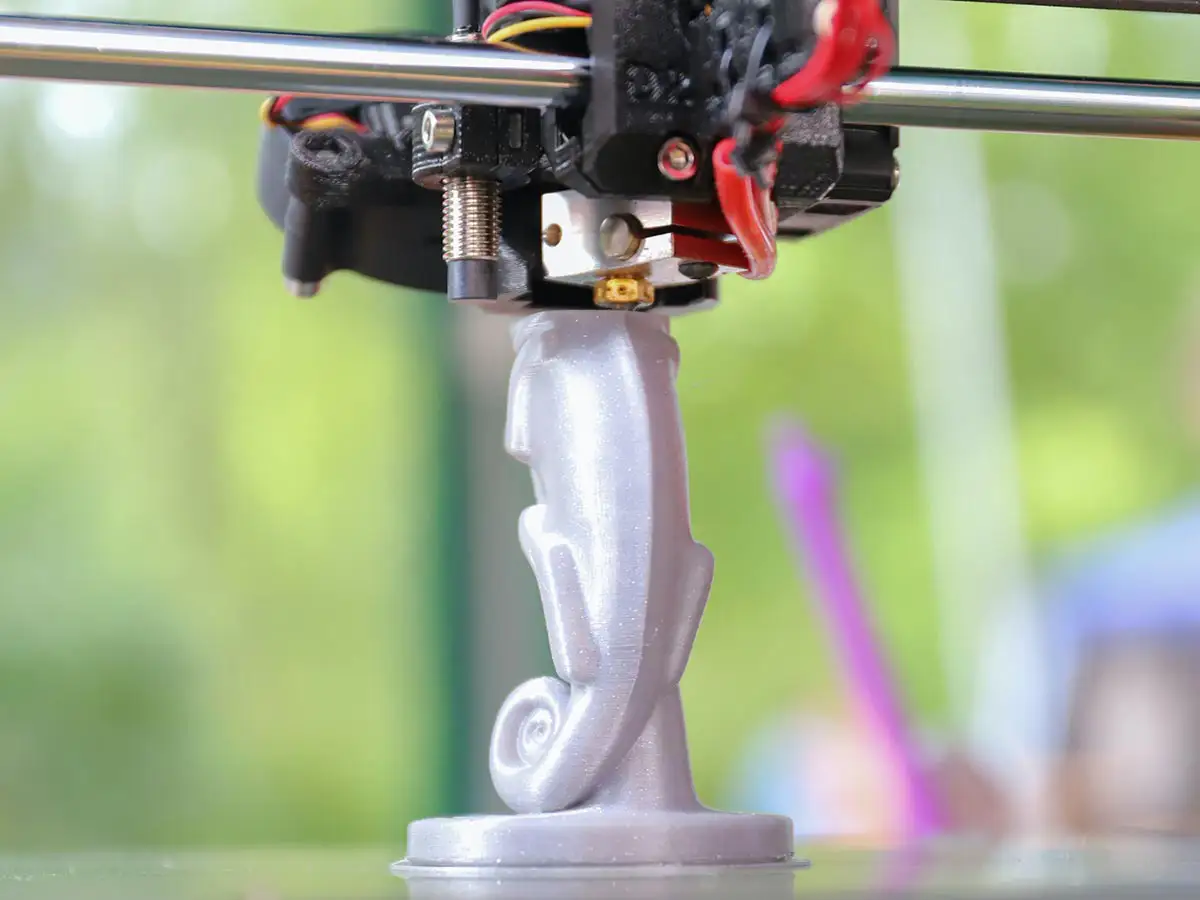

3D printing is a valuable tool used by commercial businesses, industrial manufacturers, and hobbyists. The flexibility provided by 3D printers allows both businesses and hobbyists to print parts tailored to fit a specific application or project. By directly printing a specific part, tooling, molds, and the time and labor associated with creating the part may be sidestepped, lowering the costs associated with the creation of the part. Interstate Advanced Materials provides a range of 3D printing services through valued partners to provide cost-effective material solutions for custom parts tailored to fit your project.