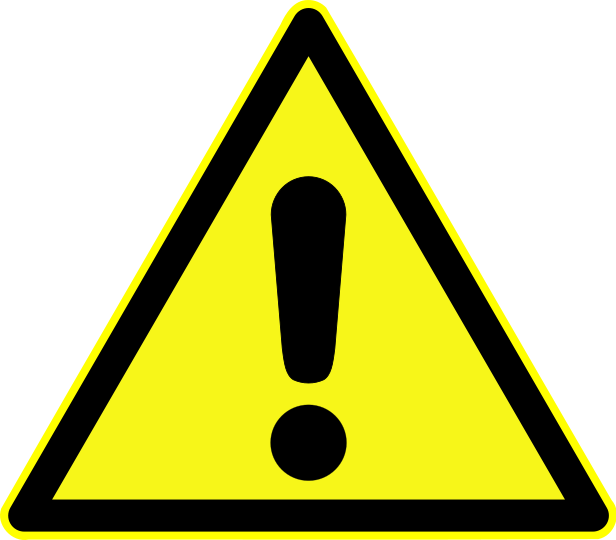

WARNING: The products on this page can expose you to chemicals including Acrylonitrile, CAS 107-13-1, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Styrene, CAS 100-42-5, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Bisphenol A, CAS 80-05-7, which are known to the State of California to cause birth defects or other reproductive harm. For more information go to www.p65warnings.ca.gov.

WARNING: The products on this page can expose you to chemicals including Polyvinyl Chloride, CAS 9002-86-2, which are known to the State of California to cause cancer. For more information go to www.p65warnings.ca.gov.