Cut-To-Size Items are Non-Returnable!

As per our Shipping and Returns Policy, custom cuts and fabricated parts are non-returnable. If you need an over- or undersized item, note it under \"Comments\" during Checkout. Cut-to-size orders have an acceptable cut tolerance of 1/8" (0.125"), so clarify if the adjustment is to be made on the (+) or (-) side of the saw blade. Please review our full return and shipping policy here.

Measure Twice, Cut OnceSince custom cuts and fabricated parts are non-refundable, be very careful while measuring your dimensions. As each cut is nominal, even the slightest miscalculation could be costly.

How to Use a Measuring TapeExtend your tape measure several inches to find the 1 and 2 inch markers. In between the inch markers you’ll find 16 equally spaced tick marks.

Measure by counting the increments beyond the nearest inch. As the increments decrease, so does the length of the mark. For example, 1/2\" has a bigger mark than 1/4\" which has a bigger mark than 1/8\". The smallest mark follows at 1/16\". Please be aware that some measuring tapes may have even smaller increments.

Features of a Measuring Tape: Sliding End HookThe sliding end hook is designed for two different types of measurements. An outside measurement (where the hook of the tape hangs over an edge), requires the hook to slide out a bit to account for the thickness of the material. When making an inside measurement (where the hook will push up against a surface), the clip slides in, again, accounting for its thickness. The measuring tape self-adjusts to guarantee an accurate measurement (as far as the tape is concerned).

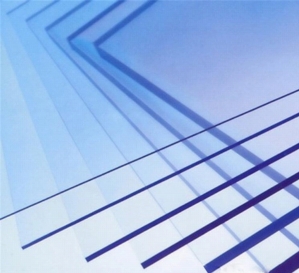

PETG VIVAK® Transparent Thermoplastic Sheet

Vivak® - Polyethylene Terephthalate Glycol

Select your custom cut sizes:

Description

PETG Vivak® sheet exhibits excellent resistance to chemicals and impacts. It has a higher impact resistance than acrylic and is more cost-effective than polycarbonate. PETG Vivak® operates between 250F to 320F and is FDA approved. It is easily fabricated and thermoformed and may be used for shelving, POP displays, merchandise racks, signage, and more.

[PDF Product Information Sheet]

- Excellent transparency and high gloss surface

- Easily fabricated consistent transparency

- Cost-effective

- High Impact resistance, similar to polycarbonate

- Break elongation similar to polycarbonate

- Easily thermoformable

- Excellent chemical resistance

- Reduces sound transmission

- Able to be sterilized easily

| Physical Properties of Vivak® PETG | |

|---|---|

| Property | PETG |

| Specific Gravity | 1.27 |

| Tensile Strength | 7700 psi |

| Tensile Modulus | 320 ksi |

| Flexural Strength | 11200 psi |

| Flexural Modulus | 310 ksi |

| Rockwell Hardness | R115 |

| Water Absorption 24H | 0.2% |

| Izod Impact, Notched (ft-lb/in.) | 1.7 |

| Heat Deflection Temp. @ 263psi | 157?F |

| Forming Temperature | 280-320?F |

| Light Transmission | 86% |

Product Reviews

1.9 out of 5 starsBy Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By Smith on March 17, 2024

3

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

By on March 17, 2024

Specifications

Specific Gravity (g/cc): 1.27

Water Absorption: 0.2% @ 24H

Tensile Strength: 7700 psi

Tensile Modulus: 320.3 ksi

Flexural Modulus: 310 ksi

Flexural Strength: 11200 psi

Izod Impact Strength: 1.7 ft-lb/in.

Hardness: R115

Compressive Strength: 8000 psi

Heat Deflection Temp: 164?F @ 66 psi / 157?F @ 264 psi

Self Ignition Temp: 880?F

UL94 Flammability: HB

Dielectric Constant: 2.4 @ 1 Mhz

Frequently Asked Questions

What sets Interstate Advanced Materials apart?

Interstate Advanced Materials empowers customers to choose their pricing by maintaining a membership, available through tier levels that unlock access to exclusive pricing as well as shipping and volume discounts

What is Interstate Advanced Materials's Shipping Policy?

Shipping will vary based on whether your order contains custom or cut-to-size products. Details about shipping can be found here.

Is Interstate Advanced Materials site secure?

Absolutely. Your information is passed through our https site when you make a purchase. Your Credit Card is never stored on file.