Cut-To-Size Items are Non-Returnable!

As per our Shipping and Returns Policy, custom cuts and fabricated parts are non-returnable. If you need an over- or undersized item, note it under \"Comments\" during Checkout. Cut-to-size orders have an acceptable cut tolerance of 1/8" (0.125"), so clarify if the adjustment is to be made on the (+) or (-) side of the saw blade. Please review our full return and shipping policy here.

Measure Twice, Cut OnceSince custom cuts and fabricated parts are non-refundable, be very careful while measuring your dimensions. As each cut is nominal, even the slightest miscalculation could be costly.

How to Use a Measuring TapeExtend your tape measure several inches to find the 1 and 2 inch markers. In between the inch markers you’ll find 16 equally spaced tick marks.

Measure by counting the increments beyond the nearest inch. As the increments decrease, so does the length of the mark. For example, 1/2\" has a bigger mark than 1/4\" which has a bigger mark than 1/8\". The smallest mark follows at 1/16\". Please be aware that some measuring tapes may have even smaller increments.

Features of a Measuring Tape: Sliding End HookThe sliding end hook is designed for two different types of measurements. An outside measurement (where the hook of the tape hangs over an edge), requires the hook to slide out a bit to account for the thickness of the material. When making an inside measurement (where the hook will push up against a surface), the clip slides in, again, accounting for its thickness. The measuring tape self-adjusts to guarantee an accurate measurement (as far as the tape is concerned).

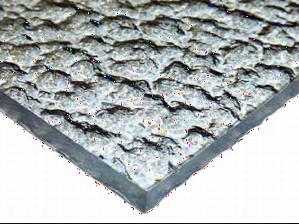

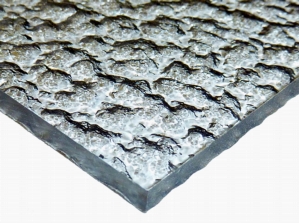

POLYCARBONATE SHEET | CLEAR #80 PEBBLE

Pebble Texture Polycarbonate

Price for .118 x 48 x 96" Sheet Qty: 1

ESTIMATED SHIPPING TO 43085: $400.00

Description

Pebble textured polycarbonate lets light in while obstructing the view of objects behind it. It is a high strength anti-vandalism material that is perfect for security barriers, windows and panels. Polycarbonate is a versatile, tough plastic used for a variety of applications, from bulletproof windows to compact disks (CDs). It comes in transparent and opaque varieties. The main advantage of polycarbonate over other types of plastic is unbeatable strength combined with light weight. Polycarbonate is much lighter than glass, and is nearly unbreakable. Bullet-resistant variations are available and are used in windows and enclosures usually seen inside banks are often made of polycarbonate. How to Clean Polycarbonate Sheet General Cleaning Removing Oil and Tar Removing Heavy Markings (e.g. graffiti, paint, marker, inks, glazing components) Removing Adhesive-Backed Labels Removing Scratches Special Note: Always rinse edges of polycarbonate with generous amounts of warm water, as the edges of polycarbonate sheet are not protected with an abrasion and chemical resistance hard coating.

1. Rinse surface with warm water to loosen preexisting dust, dirt and grime.

2. Gently wash surface with a mild soap and a soft microfiber cloth or sponge.

3. Rinse thoroughly with lukewarm water. Dry completely with a soft, dry cloth.

1. Rinse with warm water to loosen preexisting dust, dirt and grime.

2. Gently rub surface with a 50/50 isopropyl alcohol and water mixture using a soft, non-abrasive cloth.

3. Immediately rinse material with water and dry using a soft, dry cloth.

1. Rinse with warm water to loosen preexisting dust, dirt and grime.

2. Gently rub surface with Naphtha VM&P grade, isopropyl Alcohol, or butyl cellosolve, using a soft, non-abrasive cloth.

1. Stubborn adhesives can be removed using isopropyl alcohol, Naphtha VM&P grade or kerosene.

1. Deep scratches and gouges made by sharp objects such as keys, screwdrivers and knives cannot be repaired.

2. Fine scratches can be cosmetically hidden by using our Novus 2, followed by a polishing agent such as Novus 1.

- Virtually unbreakable with extreme impact resistance

- High dielectric strength

- Easily machinable

- Transparent up to 2" thick

- Wide temperature operating range (-40?F to 280?F)

- Lightweight

NEED A POLYCARBONATE SAMPLE?

Thermoplastics Material Sample Pack

Impact Strength Material Sample Pack

Specifications

Specific Gravity (g/cc): 1.19

Water Absorption: 0.15% @ 24H / 0.35% @ Saturation

Density: 1.2 g/cm3

Friction Coefficient: 0.38

Tensile Strength: 8700 psi (Yield)

Tensile Modulus: 300 ksi

Flexural Modulus: 340 ksi

Flexural Strength: 14200 psi

Elongation: 50% @ Break

Izod Impact Strength: 2 ft-lb/in.

Hardness: M70, R118

Compressive Strength: 12500 psi

Compressive Modulus: 345 ksi

Continuous Operating Temp: 240?F

Intermittent Operating Temp: 275?F

Heat Deflection Temp: 280?F @ 66 psi / 270?F @ 264 psi

UL94 Flammability: HB

Linear Expansion Coefficient: 3.6 x 10-5/?F

Dielectric Constant: 2.96

Dissipation Factor: 0.0009

Frequently Asked Questions

What sets Interstate Advanced Materials apart?

Interstate Advanced Materials empowers customers to choose their pricing by maintaining a membership, available through tier levels that unlock access to exclusive pricing as well as shipping and volume discounts

What is Interstate Advanced Materials's Shipping Policy?

Shipping will vary based on whether your order contains custom or cut-to-size products. Details about shipping can be found here.

Is Interstate Advanced Materials site secure?

Absolutely. Your information is passed through our https site when you make a purchase. Your Credit Card is never stored on file.