Cut-To-Size Items are Non-Returnable!

As per our Shipping and Returns Policy, custom cuts and fabricated parts are non-returnable. If you need an over- or undersized item, note it under \"Comments\" during Checkout. Cut-to-size orders have an acceptable cut tolerance of 1/8" (0.125"), so clarify if the adjustment is to be made on the (+) or (-) side of the saw blade. Please review our full return and shipping policy here.

Measure Twice, Cut OnceSince custom cuts and fabricated parts are non-refundable, be very careful while measuring your dimensions. As each cut is nominal, even the slightest miscalculation could be costly.

How to Use a Measuring TapeExtend your tape measure several inches to find the 1 and 2 inch markers. In between the inch markers you’ll find 16 equally spaced tick marks.

Measure by counting the increments beyond the nearest inch. As the increments decrease, so does the length of the mark. For example, 1/2\" has a bigger mark than 1/4\" which has a bigger mark than 1/8\". The smallest mark follows at 1/16\". Please be aware that some measuring tapes may have even smaller increments.

Features of a Measuring Tape: Sliding End HookThe sliding end hook is designed for two different types of measurements. An outside measurement (where the hook of the tape hangs over an edge), requires the hook to slide out a bit to account for the thickness of the material. When making an inside measurement (where the hook will push up against a surface), the clip slides in, again, accounting for its thickness. The measuring tape self-adjusts to guarantee an accurate measurement (as far as the tape is concerned).

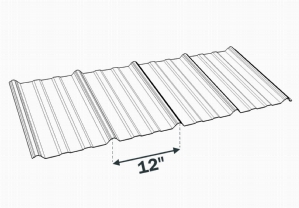

SUNSKY 12 WHITE OPAL CORRUGATED POLYCARBONATE SHEET

Corrugated Polycarbonate Rooflite And Sidelite Panels

ESTIMATED SHIPPING TO 06828: $75

Description

Note: Must be ordered in increments of 10. Orders of less than 10 sheets will be refunded. SunSky corrugated polycarbonate turns night into brilliant daylight, transforming factories, assembly lines, agricultural buildings, and livestock shelters into well-lit areas that reap the benefits of natural sunlight. SunSky is compatible with popular metal panel profiles, making it a perfect choice for seamless skylights, roof lights, and sidelights. Durable SunSky has had no mechanical failures or cracks at the end of any test to measure ultimate load when tested to ICBO Evaluation Service Acceptance Criteria, AC 16 Plastic Skylights. This high-performance glazing material stands up to punishing exterior applications, offering many advantages over traditional fiberglass corrugated panels: up to 20 times greater impact resistance, the highest light transmission rates, the lowest yellowing index, the highest load rating, and the highest resistance to wind uplift-outstanding properties confirmed in accredited laboratory testing.

- Matches virtually any profile

- Virtually unbreakable

- Self extinguishing

- Resistant to yellowing

- Retains optical clarity with high light transmission

- Can handle extreme climates (-40?F to 250?F)

- Easily and safely installed

- ICC-ES Approved

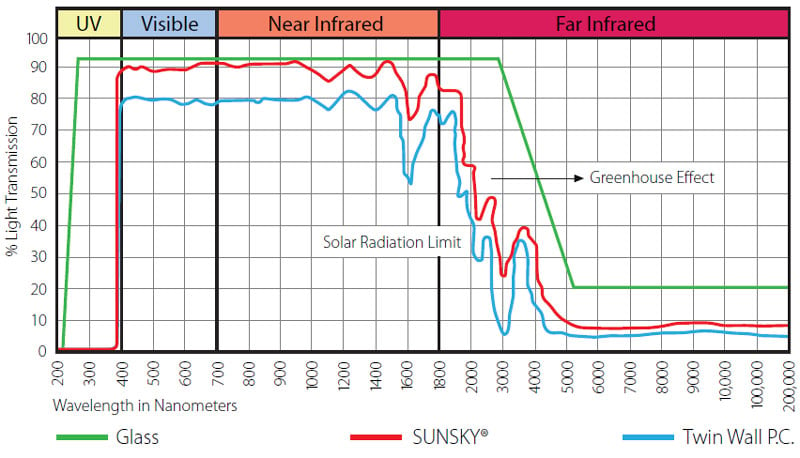

Radiation Filtering: SunSky panels form a complete shield against harmful ultraviolet rays, while admitting most of the visible light, essential to healthy livestock and work environments. By completely blocking the far infrared rays, SunSky prevents heat loss at night. SunSky blocks both UV-A and UV-B, which prevents damage to items located underneath the panels due to UV exposure.

Thermal Insulation & Light Transmission: SunSky's heat conductivity is lower than fiberglass (FRP) sheets, which can result in considerable heating cost savings, compared to fiberglass.

| SunSky Color | Light Transmission | Solar Heat Gain Coefficient (SHGC) | Shading Coefficient (SC) | Diffusion |

| Clear | 90% | 0.90 | 1.04 | n/a |

| White Opal | 45% | 0.51 | 0.59 | 100% |

| Soft White | 85% | 0.85 | 0.98 | 100% |

?

Superior Weathering: With a built-in co-extruded UV blocking layer, SunSky maintains its light transmission and physical properties while being resistant to yellowing. Arizona climatic exposure tests and accelerated QUV tests indicate a significant advantage of SunSky over competitive products such fiberglass.

Specifications

Water Absorption: .15% @ 24 hrs

Density: 1.2 g/cm3

Tensile Strength: 9000 psi @ Yield

Tensile Modulus: 345 ksi

Flexural Modulus: 345 ksi

Flexural Strength: 13500 psi

Elongation: 6% @ Yield

Izod Impact Strength: 15 ft-lb/in.

Hardness: R125/M70

Heat Deflection Temp: 270?F

Vicat Softening Temp: 300?F

Linear Expansion Coefficient: 3.6 x 10-5/?F

Dielectric Constant: 3

Dissipation Factor: .9

Frequently Asked Questions

What sets Interstate Advanced Materials apart?

Interstate Advanced Materials empowers customers to choose their pricing by maintaining a membership, available through tier levels that unlock access to exclusive pricing as well as shipping and volume discounts

What is Interstate Advanced Materials's Shipping Policy?

Shipping will vary based on whether your order contains custom or cut-to-size products. Details about shipping can be found here.

Is your site secure?

Yes, we implement a variety of security measures to maintain the safety of your personal information. Your information is protected both online and offline.