Cut-To-Size Items are Non-Returnable!

As per our Shipping and Returns Policy, custom cuts and fabricated parts are non-returnable. If you need an over- or undersized item, note it under \"Comments\" during Checkout. Cut-to-size orders have an acceptable cut tolerance of 1/8" (0.125"), so clarify if the adjustment is to be made on the (+) or (-) side of the saw blade. Please review our full return and shipping policy here.

Measure Twice, Cut OnceSince custom cuts and fabricated parts are non-refundable, be very careful while measuring your dimensions. As each cut is nominal, even the slightest miscalculation could be costly.

How to Use a Measuring TapeExtend your tape measure several inches to find the 1 and 2 inch markers. In between the inch markers you’ll find 16 equally spaced tick marks.

Measure by counting the increments beyond the nearest inch. As the increments decrease, so does the length of the mark. For example, 1/2\" has a bigger mark than 1/4\" which has a bigger mark than 1/8\". The smallest mark follows at 1/16\". Please be aware that some measuring tapes may have even smaller increments.

Features of a Measuring Tape: Sliding End HookThe sliding end hook is designed for two different types of measurements. An outside measurement (where the hook of the tape hangs over an edge), requires the hook to slide out a bit to account for the thickness of the material. When making an inside measurement (where the hook will push up against a surface), the clip slides in, again, accounting for its thickness. The measuring tape self-adjusts to guarantee an accurate measurement (as far as the tape is concerned).

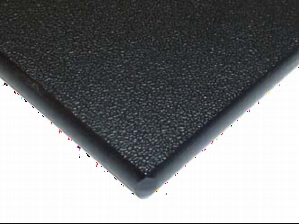

KING STARLITE® SHEET | BLACK XL UTILITY

Marine-grade High Density Polyethylene

Select your custom cut sizes:

Description

King Starlite XL Utility is an economical cellular (closed cell) utility sheet made from select high-grade King Starboard recycled high-density polyethylene. It is ideal for boat parts, as an upholstery substrate, and in other behind-the-scenes applications where edges aren't visible. King Starlite XL Utility is up to 35% lighter in weight than King Starboard and it offers the same quality textured surface on both sides. King Starlite XL Utility is specially formulated to withstand the rigors of harsh outdoor marine environments. It is UV-stabilized to resist damage and retain its beauty, even after years of direct sunlight. It does not splinter, crack, delaminate, rot, swell, or absorb water like traditional materials. Even under heavy foot traffic on yacht decks, it remains virtually maintenance-free. In addition, there is no need to stain or paint. Fabricating and finishing King Starlite XL Utility is easy with standard woodworking tools. King Starlite XL Utility forms easily for smooth curves and bends. Since there is no grain pattern, parts can be cut from any part of the sheet, virtually eliminating waste (meaning greater economy versus wood). Special Notes:

Available in colors black, white, grey

Please expect 15 day delivery for this item.

King Starboard Specs, Grades & Applications ?

King Starlite XL Utility sheets are up to 35% lighter in weight than regular King Starboard, and are made with the same textured surface and colors for a perfect match. Full sheet sizes are 60" wide and 96" long. Black and white are most readily available.

- Easy to fabricate and machine

- Extremely durable

- Flexes without breaking (unlike plywood or PVC foam products)

- Unique (closed-cell) cellular marine-grade sheet

- Weighs 30% less than traditional King Starboard

- Resistant to rotting, swelling, splintering and delaminate

- Environmentally stabilized for harsh sun and marine environments

- Resistant to odor, acid, alcohol and bases

- Easy to clean

- Proven on thousands of bats and yachts

- Matte-textured finish on both sides

Specifications

Specific Gravity (g/cc): 0.77

Water Absorption: 0.10% @ 24H

Density: .77 & .7187 g/cm3

Tensile Strength: >3300 psi

Tensile Modulus: 165 ksi

Flexural Modulus: 130 ksi

Flexural Strength: 3000 psi

Elongation: 9.6% @ Yield

Izod Impact Strength: 1.4 ft.-lb/in.

Hardness: 64.9 (Shore D)

Heat Deflection Temp: 188?F

UL94 Flammability: HB

Frequently Asked Questions

What sets Interstate Advanced Materials apart?

Interstate Advanced Materials empowers customers to choose their pricing by maintaining a membership, available through tier levels that unlock access to exclusive pricing as well as shipping and volume discounts

What is Interstate Advanced Materials's Shipping Policy?

Shipping will vary based on whether your order contains custom or cut-to-size products. Details about shipping can be found here.

Is Interstate Advanced Materials site secure?

Absolutely. Your information is passed through our https site when you make a purchase. Your Credit Card is never stored on file.